The folks over at LinkSprite have a pretty informative Wiki for desktop CNC.

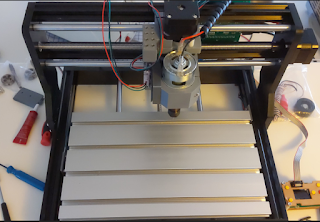

One of my first CNC projects was this op-amp circuit etched into a bar of soap . (turns out soap is pretty forgiving, and a great way to learn to use a CNC machine). After a couple of sample runs, and my limited free time, it ended up mostly sitting idle in a box. So many cool projects, so little time.

It was about a year later during the summer of 2019 that I ordered the original Prusa i3 mk3s kit. This, too was quite a fun assembly project - although considerably more challenging than the CNC machine. I spent pretty much an entire weekend putting this together. It was really quite rewarding. The assembly instructions are very clear. The process is however quite time consuming. Plus, now I have a new appreciation for gummy bears.

After assembly and a download or two from ThingVerse, my interest (and free time) waned somewhat. I had poked around a bit with various CAD programs, but nothing really sparked my interest. in printing designs from someone else. The printer then sat idle, too.

So here we are in 2020. I have SO MUCH more free time. Although I put in more hours for the Day Job from home, we don't travel or do much else these days. This leaves plenty of time to explore all these things I've wanted to learn!

It was a couple of months ago that I bought my next item on my list of "always wanted to have, but not sure what I will actually do with it": A reflow oven! I had a lot of fun retrofitting this as described in my prior blog. (it's no fun just to buy something, right?)

Oddly, this was also the project to bring everything together. I thought it would be cool to etch my own Mylar solder stencil to try out my first SMD PCB: a reason to use the CNC machine! Oh, but the CNC machine needs those limit switches. I can print my own limit switch hardware! Oh, but I had pretty limited experience with mechanical CAD design. I need to learn Fusion360. Good thing that I have plenty of free time at home; chasing another bunny...

Printed books are great for reference, but not the best way to learn something hands-on like CAD software. Yes, there are a lot of YouTube videos, but most seem to be people showing off what can be done, instead of actually teaching the complete newbie, like me. Solution? This Designing for 3D Printing with Fusion 360 on Udemy This is absolutely an awesome class that got me kickstarted in Fusion 360. If you have little or no skills with Fusion 360, I highly recommend this class. Vladimir Mariano is clear, concise, articulate, and a real joy to learn from in this class.

Being able to design parts and print them at home turns out to be quite addicting, particularly if you happen to be a borderline perfectionist. There's somewhat of a chronology in my learning and skills here:

There's apparently a Grbl plug-in for OctoPrint; I'll need to take that for a test drive.

Enough of the background... on to the mounting hardware design...

Resources, Inspiration, Credits, and Other Links:

Copyright (c) gojimmypi all rights reserved. Blogger Image Move Cleaned: 5/3/2021 1:35:54 PM